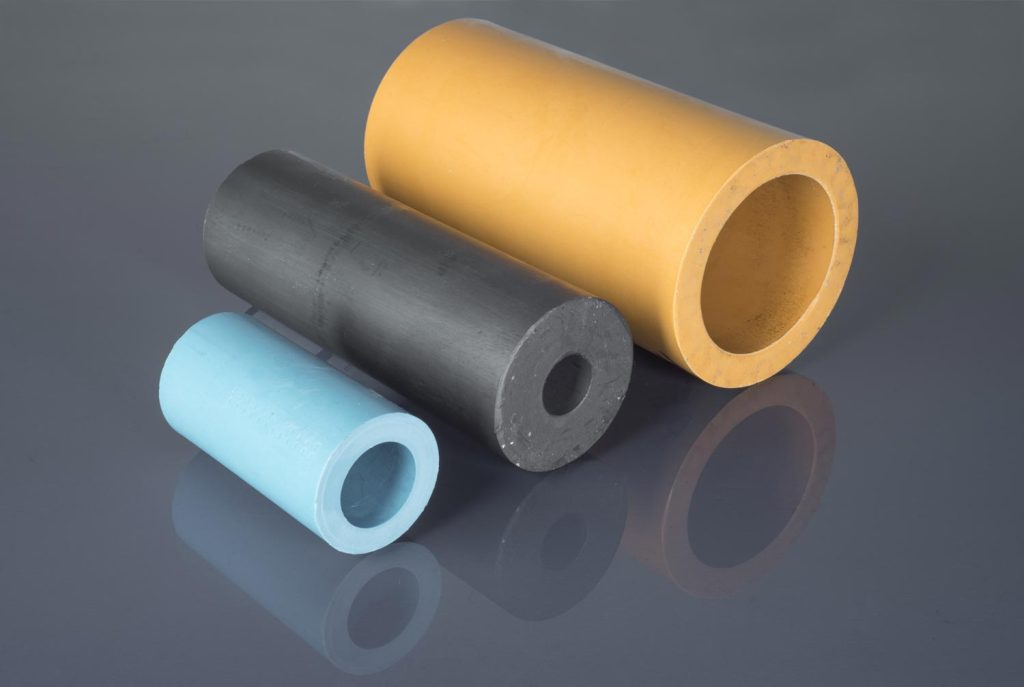

Polytetrafluoroethylene (PTFE), known as Teflon™, is prized for its chemical resistance, low friction, and broad temperature tolerance. While widely used across industries, pure PTFE has drawbacks like low wear resistance and poor dimensional stability. To address these, engineers add fillers, creating filled PTFE.

Filled PTFE is a customizable material designed to enhance specific properties such as strength, wear resistance, and thermal conductivity. This makes it ideal for high-performance applications where standard PTFE falls short.

Why Add Fillers to PTFE?

Unfilled PTFE offers impressive qualities such as:

- Excellent chemical inertness

- Broad thermal stability (up to 260°C)

- Low coefficient of friction

- Non-stick and non-wetting surface characteristics

However, it also has some drawbacks:

- Low wear resistance

- High thermal expansion

- Poor load-bearing capacity

- Tendency to creep under stress

By adding fillers, manufacturers can customize PTFE to perform better in challenging environments without sacrificing its core benefits. The choice of filler depends on the desired combination of properties for a particular application.

Common Fillers and Their Benefits

Here are the most widely used fillers and the enhancements they provide to PTFE:

- Glass Fiber

- Benefits: Increases compressive strength, stiffness, and wear resistance

- Applications: Seals, valve seats, and electrical insulators

- Notes: Maintains good chemical resistance, but not ideal for hydrofluoric acid exposure

2. Carbon

- Benefits: Improves wear resistance, compressive strength, and thermal conductivity

- Applications: Bearings, thrust washers, compressor rings

- Notes: Some reduction in electrical insulation properties

3. Graphite

- Benefits: Excellent self-lubrication, reduces friction even in dry conditions

- Applications: Sliding components, dry-running bearings

- Notes: Often combined with other fillers like glass or carbon

4. Bronze

- Benefits: Greatly enhances wear resistance and thermal conductivity

- Applications: High-load bearings, piston rings

- Notes: Reduced chemical resistance compared to other fillers

5. Molybdenum Disulfide (MoS₂)

- Benefits: Increases surface hardness, reduces friction

- Applications: Dynamic seals, wear rings, automotive parts

- Notes: Often used with glass or bronze for a balanced performance profile

6. Stainless Steel or Nickel

- Benefits: Provides electrostatic dissipation, improves strength and heat conductivity

- Applications: Chemical and semiconductor industries

- Notes: Adds weight and can impact chemical resistance

Applications of Filled PTFE

Filled PTFE components are found in a wide range of industries due to their tailored performance:

Aerospace

- Bushings, seals, and bearings in high-temperature and high-friction zones

- Enhanced reliability under extreme thermal and mechanical stress

Automotive

- Gaskets, piston rings, and wear pads

- Withstands friction and vibration over extended periods

Medical

- Surgical tools and implantable components using biocompatible fillers

- Maintains stability under sterilization and bodily fluids

Electronics

- Insulating parts, connectors, and housings

- Certain fillers allow for control over dielectric properties

Chemical Processing

- Valve seats, gaskets, and pipe linings

- Maintains chemical integrity while improving mechanical durability

Considerations When Choosing Filled PTFE

While filled PTFE offers numerous advantages, it also introduces trade-offs that must be evaluated based on the application’s requirements:

- Chemical Resistance: Some fillers may compromise PTFE’s universal chemical inertness

- Electrical Properties: Conductive fillers reduce dielectric strength, limiting electrical insulation applications

- Machinability: Filled PTFE can be more abrasive to tools, requiring specialized equipment and expertise

- Cost: Filled PTFE is typically more expensive than unfilled PTFE and other polymers

To make the most of filled PTFE, designers and engineers must carefully match filler properties to the specific performance needs of their application.

Optimize Your Application with Filled PTFE

Machining-filled PTFE requires adjustments compared to metals or standard plastics. Using sharp carbide tools, managing heat buildup with coolant or air, and properly securing the material to avoid deflection are essential. Accounting for thermal expansion and dimensional creep is also key to maintaining precision. Working with skilled machinists experienced in high-performance plastics ensures better control and high-quality results.

Filled PTFE is a versatile solution for demanding applications where unfilled PTFE or traditional plastics fall short. From aerospace bushings to chemical-resistant seals, selecting the right filler and expert supplier helps optimize performance, extend part life, and enhance system reliability.