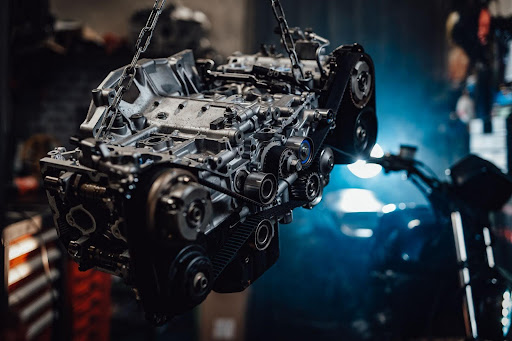

Infiniti engines from the Japanese domestic market represent the excellence of Nissan engineering applied to high-performance luxury vehicles. These sophisticated propulsion units, developed specifically to meet the high standards of the Japanese market, combine impressive power, exceptional refinement, and advanced technologies. Exploring the unique characteristics of these engines reveals why they are considered among the most desirable for high-end automotive modification projects.

Technological Heritage and Design Philosophy

Infiniti has established its reputation on creating engines that combine exceptional performance with luxurious refinement, a philosophy particularly evident in JDM versions of its engines. The integration of technologies like variable geometry intake systems, variable valve timing, and high-pressure direct injection demonstrates the brand’s commitment to continuous innovation and technical excellence.

The evolution of Infiniti JDM engines reflects a constant quest for the perfect balance between raw power and operational smoothness. Japanese engineers have developed sophisticated solutions to minimize vibrations, optimize combustion, and maximize energy efficiency, creating engines with exceptionally refined operating characteristics even at high RPMs and loads.

The design philosophy of Infiniti JDM engines prioritizes the use of premium materials and cutting-edge technologies to create durable and high-performing propulsion units. The employment of specialized aluminum alloys, advanced tribological coatings, and sophisticated thermal management systems contributes to creating engines capable of sustained performance while maintaining their characteristic refinement.

Diverse Range and Specific Innovations

The diversity of Infiniti JDM engines extends from naturally aspirated V6s to high-performance turbocharged V8 configurations, each optimized for specific applications. The VQ series engines of the 35 and 37 variants distinguish themselves through their linear torque curves and distinctive sound signature, while VR38 units represent the state of the art in V6 turbo engines for extreme sporting applications.

Infiniti JDM naturally aspirated engines benefit from sophisticated intake technologies including variable geometry manifolds and tuned resonance systems to optimize cylinder filling across a wide RPM range. These innovations allow combining generous low-end torque with high-end power, offering remarkable versatility adapted to both urban driving and sporting performance.

Turbocharged versions of Infiniti JDM engines integrate sophisticated twin-turbo forced induction systems with optimally sized turbos to minimize lag and maximize peak power. The use of advanced intercooling systems and sophisticated electronic management allows maintaining consistent performance even during extended intensive use.

Technical Characteristics and Exclusive Innovations

Infiniti JDM engines incorporate exclusive technologies often absent from export market versions, including variable phase timing systems on both intake and exhaust. This technical sophistication allows fine optimization of engine cycles according to operating conditions, simultaneously improving performance, energy efficiency, and emissions.

Attention to reducing internal friction distinguishes Infiniti JDM engines through the use of plasma coatings on sliding surfaces and specifically formulated motor oils. These technical innovations contribute to improving mechanical efficiency while extending service intervals and reducing wear on critical moving components.

Thermal management systems integrated into Infiniti JDM engines use sophisticated cooling circuits with electric water pumps and mapped thermostats to maintain optimal operating temperatures in all conditions. This precise temperature management improves combustion efficiency and preserves the durability of heat-sensitive components.

Performance Applications and Optimization Potential

Infiniti JDM engines offer excellent optimization potential thanks to their robust construction and sophisticated electronic management systems. Naturally aspirated versions respond particularly well to intake and exhaust modifications, allowing significant power gains while preserving reliability and the original engine character.

Turbo Infiniti JDM units present even greater improvement possibilities through optimization of forced induction systems and engine control unit reprogramming. Controlled increase in boost pressure, combined with improvements to injection and ignition systems, can unlock substantial power gains while maintaining long-term durability.

Integration of advanced monitoring systems allows owners to monitor critical operating parameters in real-time and optimize settings according to their specific needs. This scientific approach to optimization ensures maximum potential extraction while preserving the engine’s mechanical integrity.

Installation and Integration in Automotive Projects

Installing an Infiniti JDM engine requires meticulous planning to accommodate the dimensional specifics and mounting requirements of these sophisticated units. Packaging differences, particularly for V8 engines, may require substantial engine bay and auxiliary system modifications to ensure optimal integration.

The complexity of modern Infiniti JDM engine electronic systems demands specialized expertise for integrating CAN networks, multiple sensors, and sophisticated actuators. Using standalone ECUs or protocol adapters can simplify this integration while preserving access to the engine’s advanced features.

Adapting cooling systems to the specific thermal requirements of Infiniti JDM engines constitutes a crucial aspect of installation. These high-performance engines generate significant amounts of heat requiring oversized radiators and optimized ventilation systems to maintain safe operating temperatures in all usage conditions.

Specialized Maintenance and Performance Preservation

Infiniti JDM engines require sophisticated maintenance protocols to preserve their performance characteristics and exceptional refinement. Using premium quality synthetic motor oils, formulated specifically for high-performance engines, constitutes an essential investment to maintain internal component integrity and optimize engine longevity.

Service intervals for Infiniti JDM engines may require adjustments according to intended use, with more frequent changes for high-performance applications and regular checks of complex systems like variable valve timing. This preventive approach helps identify emerging problems quickly and maintain optimal performance.

Continuous monitoring of operating parameters through advanced diagnostic systems enables effective predictive maintenance and continuous performance optimization. Installing additional sensors and logging systems helps understand engine behavior in different conditions and adapt maintenance accordingly.

Acquisition Sources and Selection of Authentic Engines

Acquiring an authentic Infiniti JDM engine requires identifying reputable suppliers offering quality and authenticity guarantees. Specialists offering used JDM infiniti engines generally maintain high inspection and verification standards, ensuring that proposed engines retain their original performance characteristics and long-term reliability potential.

Prior evaluation of maintenance history and storage conditions of available JDM engines provides valuable indications of their actual condition and long-term value. Engines that have benefited from regular maintenance and proper storage generally retain their original performance and require less refurbishment investment.

Complete technical documentation accompanying authentic Infiniti JDM engines greatly facilitates installation and subsequent maintenance. This information includes performance specifications, electrical diagrams, and optimization procedures, contributing to the overall modification project success and lasting satisfaction of the enthusiast automotive owner.